English l Bulgarian

GUSSPRO LTD

The foundry of GUSSPRO LTD is a manufacturer of steel and iron casting with mechanical and heat treatment. Our products are manufactured for machine-building, metallurgical, mining, transport and processing enterprises. Up to 50% of our products are exported to various countries around the world. Maximum capacity of alloys production is 15,500 tons / year.

our services

Development of casting technology, with subsequent patternmaking and its commissioning

Production of steel and cast iron alloys according to the customer’s drawings or according to his casting patterns

Carrying out heat treatment

Performing mechanical processing

SOME OF THE ALLOYS, WHAT IS PRODUCED

Steel alloys (DIN /EN /AISI)

- Carbon GS38-60 GE200, GP240GH etc.

- Alloy GS-25CrMo4, L30GS, A6, X20Cr13, GX5CrNi19-10, GX75CrTi24 etc.

- Wear resistant steels GX120Mn12, L120G13H, GX120MnCr18-2 etc.

- Heat Resistant Alloys X15CrNiSi25-20, GX40CrNiSi25-12, X16CrNi25-20 etc.

- Acid-proof stainless steel X6CrNiTi18-11, X2CrNiMo17-12-3, X6CrNiMoTi17-12-2 etc.

Weight of castings from 2 to 7000 kg.

Cast iron alloys (DIN /EN /AISI)

- Gray iron EN-GJL-250, EN-GJL-300, EN-JL1050 etc.

- Ductile Iron EN GJS 400-15, EN GJS 400-18 LT, EN GJS 700 etc.

- Alloy Cast Iron Ni-Hard 1-4, G-X370CrMoNi18-2, G-X280Cr19 etc.

The weight of castings is 0.5 to 9000 kg.

PRODUCTION STRUCTURE

Department of design and technological preparation of production

Carpentry shop for pattern creating

Foundry workshop

Heat treatment

Finished product warehouse

Laboratory

Mechanical processing

Mechanical processing

Laboratory

Finished product warehouse

TECHNOLOGICAL PREPARATION OF PRODUCTION

When implementing the technology of casting a new part, a team of design engineers uses all the accumulated experience.

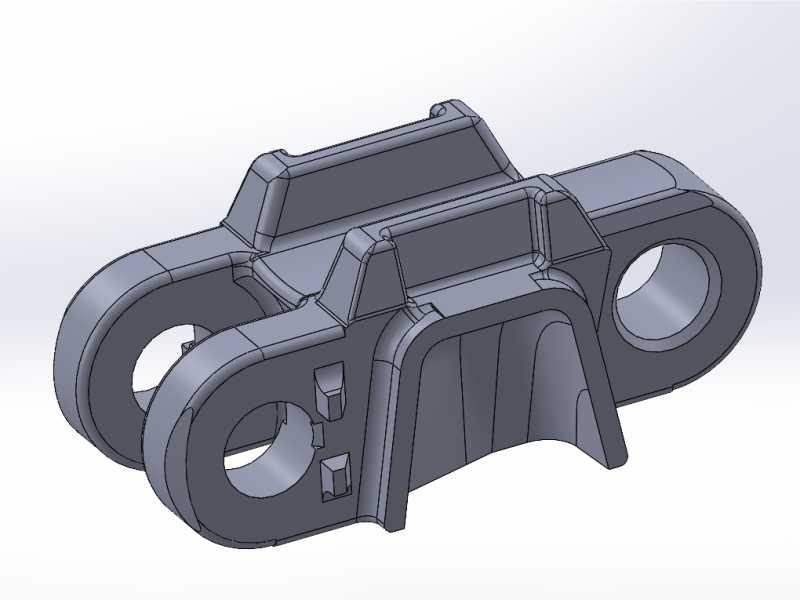

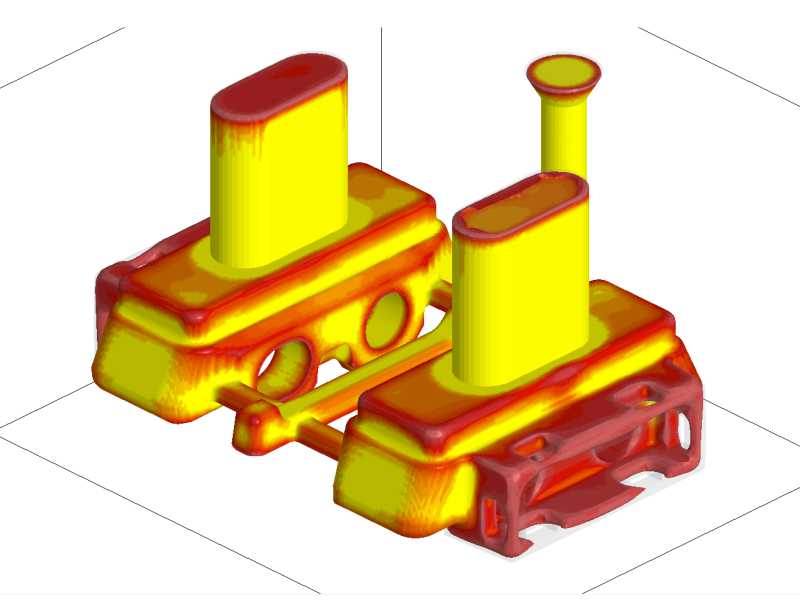

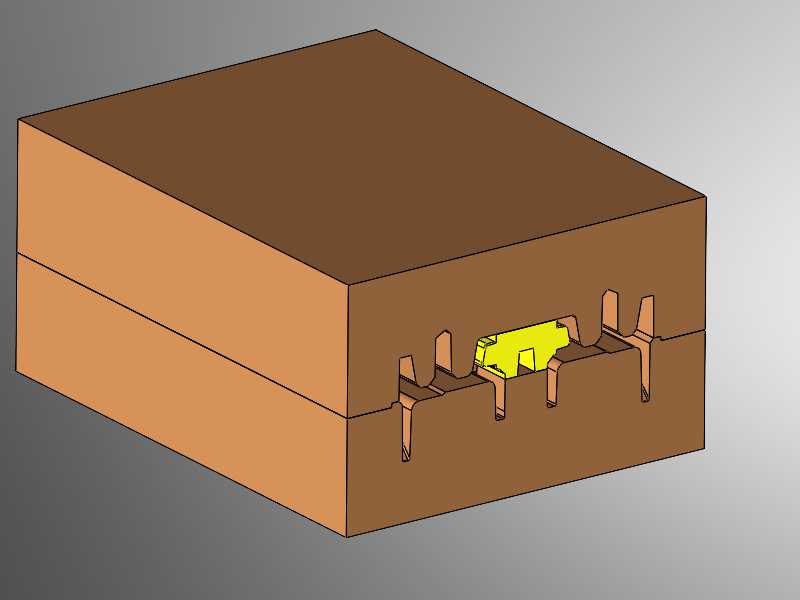

Design is performed in specialized CAD systems, at stages ranging from part modeling to mold Assembly and the crystallization process in it.

Modeling a part in 3d

Design of casting pattern

Modeling of the crystallization process

Assembling all components in the mold

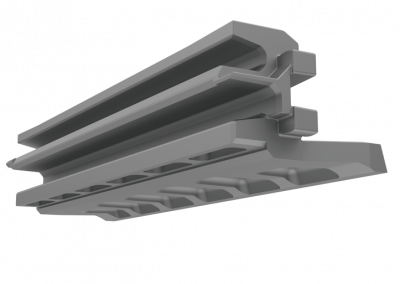

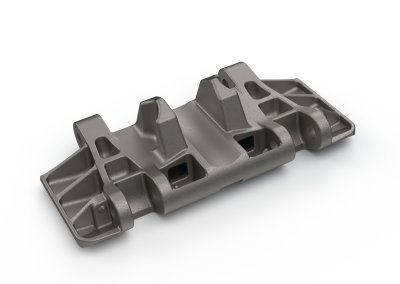

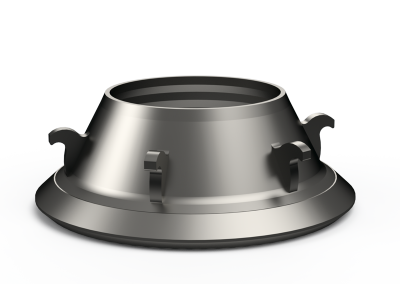

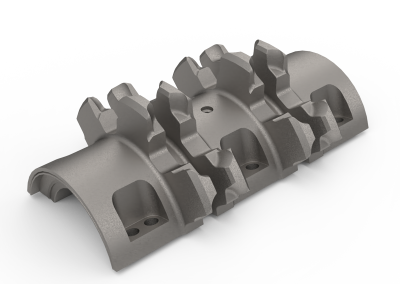

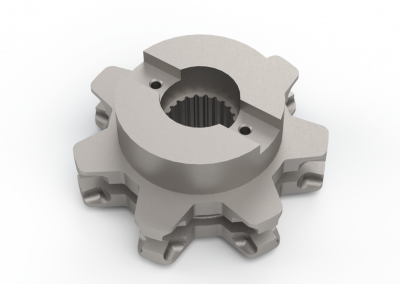

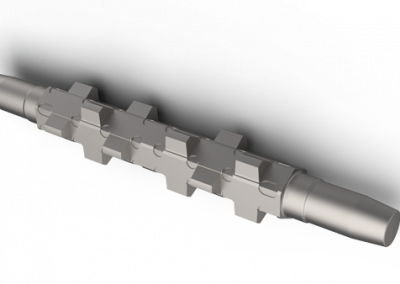

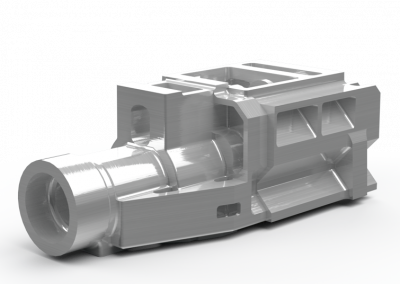

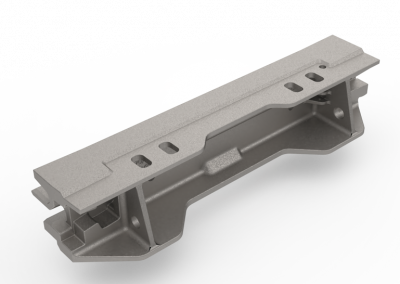

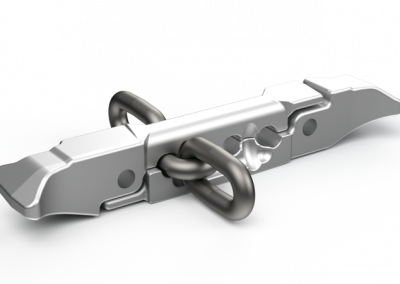

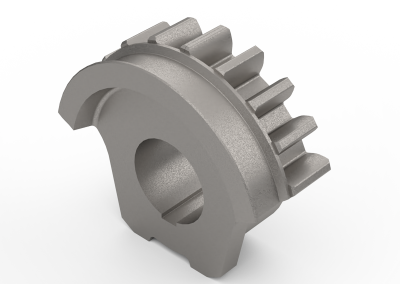

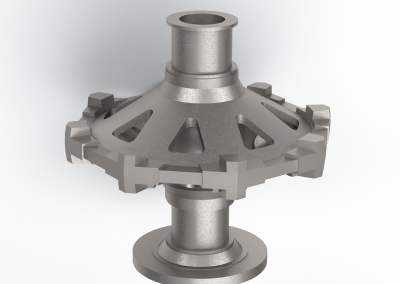

Examples of castings

PATTERNMAKING PROCESS

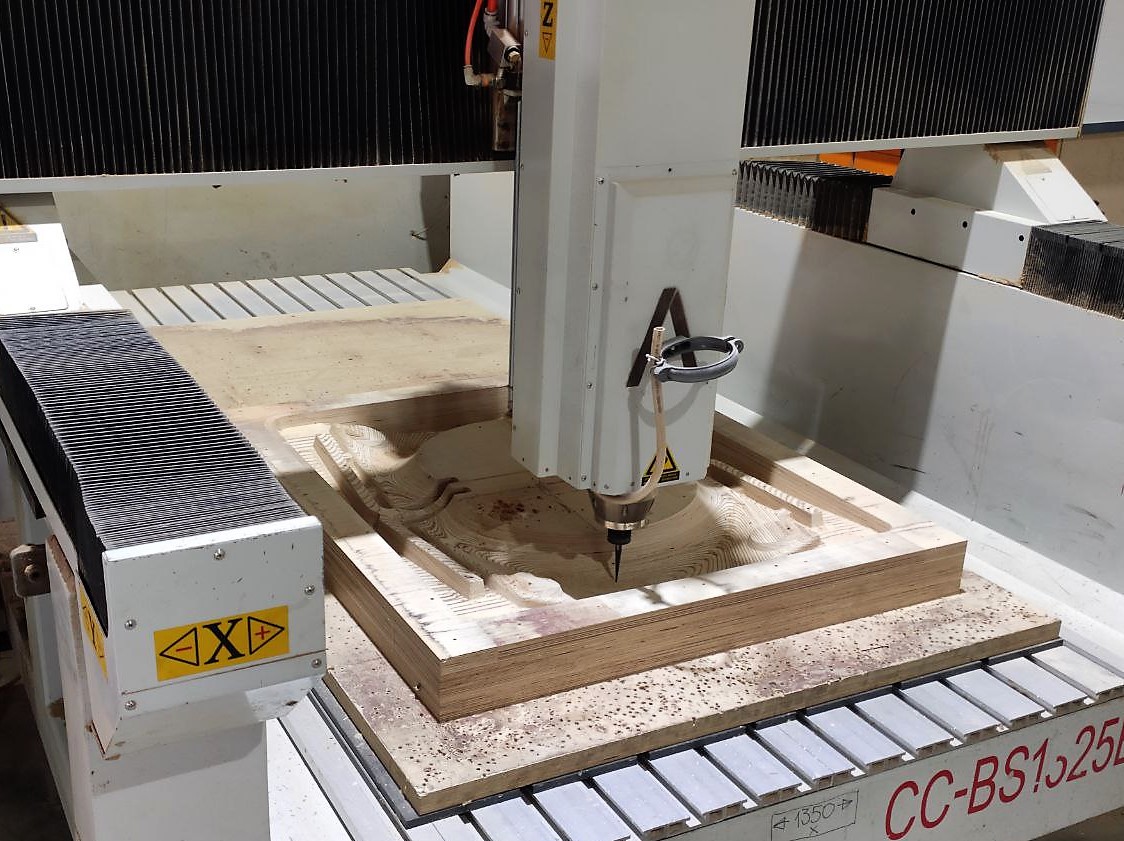

Carpentry department allows you to make patterns from wood, plastic and light colored alloys.

The production capacity of the model site includes 8 modern CNC machines, including a 5-coordinate KIMLA machining center, Siemens machines, CNC Router etc.

PRODUCTION AREAS OF THE FOUNDRY SHOP

MOLD FORMING AREA

Molds are manufactured using the no-bake foundry process based on AL FASET resins on forming machines WÖHR, FAT, with a productivity 6 to 30 tons per hour.

Casting in sand-clay mixtures (green sand process) with using forming machines HWS HSP 2, FOROMAT 40, SAVELLI with Flask sizes 1250 x 1000 x 300 x 300mm

Forming system for no-bake foundry process – WÖHR

Cores are ready for installation in the mold

PRODUCTION AREAS OF THE FOUNDRY SHOP

MELTING POINT

The plant of GUSSPRO is equipped with two-type induction furnaces Inducotherm 2x2t., and a single-type induction furnace ABB 2T, which makes it possible to simultaneously produce 5 tons of liquid metal.

At the GUSSPRO plant, Inducotherm two-needle furnaces ( 2x2t., 2x6t. 2x1t.) are installed. it is possible to simultaneously produce 11 tons of liquid metal.

The temperature of the liquid metal at discharge from the furnace and before pouring into the mold is measured by the Heraeus immersion thermocouple

PRODUCTION AREAS OF THE FOUNDRY SHOP

FINISHING OPERATIONS AREA

The finishing operations section allows you to perform the following casting operations:

• Clipping;

• Cleaning up;

• Heat treatment of castings.

They are equipped with Shot Blasting chambers and thermal furnaces, as well as mine-type furnaces.

Shot blasting of castings is carried out in Wheelabrator machines

Casting after shot blasting

Heat treatment of metal in furnaces with an exit surface measuring 4.5 x 2.6 x 1.6 m. With subsequent quenching in an aqueous or polymer medium

PRODUCTION AREAS OF THE FOUNDRY SHOP

AREA OF MECHANICAL PROCESSING OF WORKPIECES

CNC-based equipment of this section includes:

• DMG MORI mechanical processing centers;

• CNC carousel Turning Centers;

• CNC milling machines– DOOSAN;

• Boring and other machines

Carousel lathe with table diameter – 2000mm

Workpiece during the machining process

Carousel machine with table diameter 3600mm

PRODUCTION AREAS OF THE FOUNDRY SHOP

Laboratory

Full quality control at all stages of production, including:

• Quality control of incoming materials;

• Analysis of molding mixture parameters;

• Rapid analysis of the chemical composition of alloys on the Solaris CCD Plus emission spectral analyzer, Argon 5;

• Casting hardness testing;

• Mechanical properties are checked on the ZD 10/90 machine;

• Microstructure control;

• Part geometry control

Only a high-quality charge is used for melting

Solaris CCD plus emission spectrum analyzer

Checking for internal defects

Laboratory thermal furnace

FINISHED PRODUCT WAREHOUSE

EXAMPLE OF PACKAGING FINISHED PRODUCTS

Contact

+359898661068

Opening Hours

Mon-Fr, 9am – 5pm

siana.ivanova.g@gmail.com

siana_ivanova@mbox.contact.bg

GUSSPRO Ltd

s.Voyvodinovo

ul.Stopanski dvor 1

municipality Maritsa

region Plovdiv, Bulgaria

4135